How to predict bone fracture? How can we design prostheses that behave just like the patient’s bone? The CCES’s researchers Amadeus Alcântara and Caio Ramos have been trying to answer these and other questions using multiscale computational methods. To become acquainted with state-of-the-art methods, they attended a course offered by MIT between June 21 to 25, 2021.

The “Predictive Multiscale Materials Design” short course offered by MIT Professional Education and taught by Prof. Markus Buehler, a worldwide-recognized expert in the field of multiscale modeling and material design, brings together students, researchers, academics, and entrepreneurs from all around the globe. Annually held on the MIT campus, the course was adapted to an online version this year due to the COVID-19 pandemic. In this course, Prof. Buehler covers multidisciplinary topics such as bone structure, multiscale modeling, composite materials, additive manufacturing techniques, and artificial intelligence. Most of them are directly related to our researchers’ work.

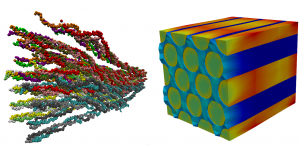

In his research, Amadeus tries to understand how osteoporosis affects bone fracture, a phenomenon that initiates at the molecular scale. Caio, on the other hand, studies 3d-printable materials, such as fiber-reinforced polymers, and tries to create prostheses that exhibit bone-like properties. While Amadeus deals with the pre-trauma scenario trying to anticipate the fracture, Caio deals with post-trauma and other surgery-mandatory scenarios, trying to provide the most suitable bone replacement. Both are Ph.D. students in the department of computational mechanics at Unicamp under the supervision of Prof. Paulo Sollero and Prof. Munir Skaf. They were awarded an MIT Academic Fellowship that covered most part of the course fee, and the CCES and FAPESP granted the remaining amount. They approach their challenging multiscale problems by performing molecular dynamics simulations and using the boundary element method: numerical methods that demand high computational power. CCES’ assistance is thus fundamental for the development of these researches since, besides financial support, the center also provides access to the Kahuna computer cluster.

The future of material design is closely related to multiscale modeling and simulations. Starting from the atoms and molecules, a comprehensive understanding of a material’s properties at each length-scale and the link between them is crucial for the design of future innovative materials and cutting-edge technologies. Indeed, that is what the MIT course has shown, further motivating our researchers to take the next step in their research.

Bone collagen fibril (left) and fiber-reinforced polymer (right).

References

Alcântara, A.C.S.; Assis, I.; Prada, D.; Mehle, K.; Schwan, S.; Costa-Paiva, L.; Skaf, M.S.; Wrobel, L.C.; Sollero, P. Patient-Specific Bone Multiscale Modelling, Fracture Simulation and Risk Analysis—A Survey. Materials 2020, 13, 106. https://doi.org/10.3390/ma13010106

Galvis, A. F.; Prada, D. M.; Moura, L. S.; Zavaglia, C.; Foster, J. M.; Sollero, P.; Wrobel, L. C. BESLE: Boundary element software for 3D linear elasticity. Computer Physics Communications 2021, 265, 108009. https://doi.org/10.1016/j.cpc.2021.108009

Grezzana, G., Loh, H., Qin, Z., Buehler, M.J., Masic, A. and Libonati, F. (2020), Probing the Role of Bone Lamellar Patterns through Collagen Microarchitecture Mapping, Numerical Modeling, and 3D-Printing. Adv. Eng. Mater., 22: 2000387. https://doi.org/10.1002/adem.202000387